Environmental Superiority of Continuous Tyre Pyrolysis Systems

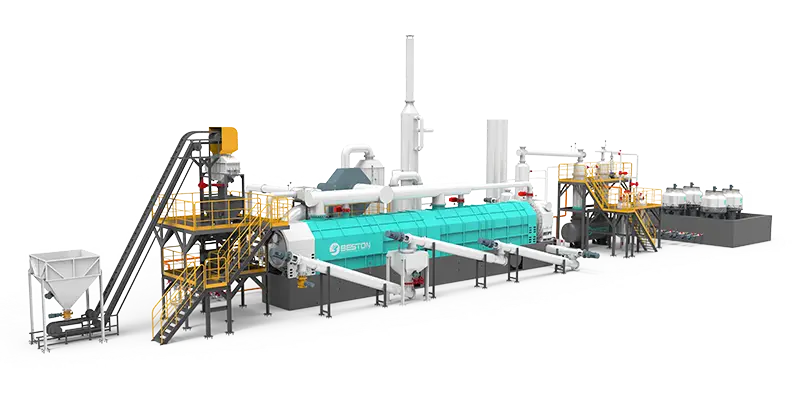

The continuous tyre pyrolysis system represents a major technological advancement in sustainable waste management. Designed to operate with precision and minimal emissions, this configuration transforms end-of-life tyres into valuable by-products while aligning with modern environmental protection standards. Its closed-loop operation, energy recovery integration, and advanced emission treatment set a new benchmark for ecological responsibility in industrial processes.

Controlled Conversion with Minimal Emissions

A continuous tire pyrolysis plant ensures that tyre decomposition occurs within a fully enclosed and oxygen-free chamber. This design prevents open combustion, a common source of air pollutants such as dioxins and nitrogen oxides. The process converts rubber compounds into gas, oil, and carbon black through thermal degradation under controlled temperatures, effectively eliminating uncontrolled emissions.

Advanced gas purification systems—typically consisting of cyclones, condensers, and scrubbers—capture volatile compounds and particulates before they reach the atmosphere. Acidic gases such as SO₂ and HCl are neutralized through chemical filtration, while dust and micro-particles are removed using high-efficiency filters. The result is a near-zero emission profile that complies with even the most stringent environmental regulations.

Energy Recovery and Circular Utilization

One of the defining ecological benefits of continuous pyrolysis systems lies in their ability to achieve energy self-sufficiency. The non-condensable gases produced during pyrolysis, rich in hydrocarbons, are redirected as a heating source for the pyrolysis reactor. This self-sustaining energy cycle eliminates the need for fossil fuel combustion, significantly reducing CO₂ emissions.

In addition, residual heat from the process is captured through heat exchangers and redirected to preheat feedstock or power auxiliary equipment. This comprehensive energy recovery approach not only minimizes waste but also contributes to the overall decarbonization of industrial operations. It exemplifies circular energy utilization, where each output stream reinforces process sustainability.

Sustainable Resource Recovery

Continuous pyrolysis systems convert waste tyres into reusable products—chiefly pyrolysis oil, recovered carbon black, steel wire, and synthetic gas. Each of these outputs holds measurable environmental value. Pyrolysis oil can substitute heavy fuel in industrial boilers, reducing dependency on virgin petroleum sources. Carbon black can be refined and reintegrated into manufacturing cycles, supporting a closed-loop resource chain.

By transforming non-biodegradable tyres into useful commodities, continuous pyrolysis technology alleviates the environmental burden of landfill accumulation and open burning. Landfill diversion not only preserves land resources but also mitigates leachate formation and microplastic contamination associated with tyre degradation.

Continuous Operation for Stable Environmental Control

Unlike batch processing, which involves repeated heating and cooling cycles, a continuous pyrolysis plant operates at steady-state conditions. This uniformity allows precise control of temperature, pressure, and gas flow, which directly influences emission stability. Steady operation prevents emission spikes during loading and unloading phases and enables consistent exhaust gas treatment.

Automated monitoring systems track critical parameters in real time. Integrated sensors and control software adjust process variables to maintain optimal combustion efficiency and minimize unburnt hydrocarbons. This continuous feedback loop ensures that environmental performance remains consistent throughout prolonged operation cycles.

Reduction of Secondary Pollution

Secondary pollution—often arising from residue handling or gas venting—is effectively mitigated in continuous pyrolysis systems. The enclosed design prevents direct exposure of by-products to air or water. Liquid residues are contained and processed internally, while solid char and steel are cooled and separated through automated systems that minimize human contact and dust dispersion.

Condensation and oil recovery units are fitted with sealing mechanisms that prevent vapor leakage. Odor control systems, such as activated carbon filters, capture organic vapors that could contribute to olfactory pollution. These integrated environmental safeguards make continuous systems particularly suitable for operation near urban or semi-industrial zones where environmental compliance is critical.

Compliance with Global Environmental Standards

Continuous tyre pyrolysis systems are designed in alignment with international environmental directives such as the EU Industrial Emissions Directive (IED) and the U.S. EPA air quality standards. Their integrated emission control units ensure compliance with limits on particulate matter, volatile organic compounds, and sulfur oxides.

Furthermore, many modern installations include real-time emissions reporting systems that transmit data to regulatory authorities, reinforcing operational transparency. Such compliance mechanisms not only safeguard ecosystems but also enhance public trust in industrial waste treatment operations.

Pathway to Carbon-Neutral Operations

By combining waste reduction, resource recovery, and energy recycling, the continuous pyrolysis plant contributes meaningfully to carbon neutrality goals. Each tonne of waste tyre processed prevents approximately 2.5 tonnes of CO₂ equivalent emissions when compared with incineration or uncontrolled disposal. The substitution of recovered oil for fossil fuels further amplifies this reduction.

When integrated with renewable electricity for auxiliary systems, the plant can achieve near-carbon-neutral operation. This capability positions continuous pyrolysis technology as a pivotal contributor to global decarbonization strategies and circular economy frameworks.

The environmental advantages of continuous tyre pyrolysis systems stem from their engineered precision and holistic process control. By merging pollution prevention, energy recovery, and sustainable material reuse, these systems transform one of the world’s most persistent waste challenges into a closed-loop industrial solution that harmonizes with environmental stewardship and sustainable development objectives.

Comments

No comments yet. Be the first to react!